♥ welcome

♥ about the bread

Created: 10 April 2010Leader: Lynnette Heng

Members: Lorelle Ang

Soh Chin Yi

Goh Ai Ting

Li Yuen Ying

♥SIP placements

Lynnette: KK Hospital- DietitianChin Yi: Gardenia- R&D

Ai Ting: Singapore Sports Council- Nutritionist

Yuen Ying: KH Roberts- lab assistant

Lorelle: OSIP (China)

Critical Limits of Chocolate Bun

Monday, May 17, 2010

FILA TEMPLATE

Sunday, May 16, 2010

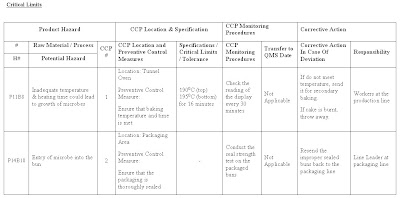

Critical Control Point of Chocolate Bun

Friday, May 14, 2010

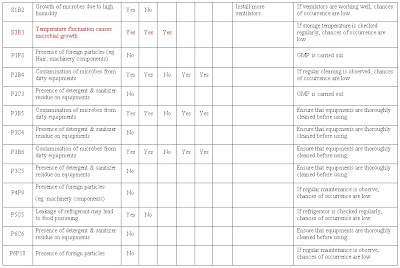

Potential Hazards & Control Procedures of Chocolate Bun

Extrinsic Factors

- Storage temperature: The buns were stored at room temperature after production. This allows a wide range of microorganisms such as psychrophiles and mesophiles to grow.

- Gaseous environment: The packaging material used to pack the buns is LDPE plastics. Although this type of packaging is a good water barrier, however, it is a poor gas barrier. Therefore, undesirable gases such as oxygen can enter the packaging. This makes it possible for microbes such as facultative aerobes to grow.

- Relative Humidity (RH): The RH of the buns during the proofing is 90%. This helps to ferment the yeast better but at the same time, it encourages the growth of molds.

- Alejandro Castillo (2004). Factors Affecting Microbial Activity in Food. Retrieved on 4th May 2010. Website: www.tamu.edu/fstc606/Handouts/Intrinsic.pdf

- Jack Eden (2001) pH Values for Common Items. Retrieved on 4th May 2010, from Jack Eden. Website: www.jackeden.com/tips/phmat.html

Intrinsic Factors

- pH: the pH of bread is usually 5-6 where it is a low acid food. Thus, most yeast and molds are able to grow well on the bread.

- Water Activity: The Aw of breads is usually 0.93-0.95. Therefore, there a lot of possible microorganism that is able to thrive. Some examples are s. aurues, molds, anterotoxin B, e.coli, pseudomonas spp. Salmonella spp., proteus spp., bacillus cereus, shigella spp., listeria monocytogene and clostridium perfringens.

- Nutrient content: Bread contains mostly of carbohydrates as it is made out of flour which are a good source of energy for microbes.

- Alejandro Castillo (2004). Factors Affecting Microbial Activity in Food. Retrieved on 4th May 2010. Website: www.tamu.edu/fstc606/Handouts/Intrinsic.pdf

- Jack Eden (2001) pH Values for Common Items. Retrieved on 4th May 2010, from Jack Eden. Website: www.jackeden.com/tips/phmat.html

Product Recall Procedure for Chocolate Bun

For Chocolate Bun, it is a Class 1 Recall

Product Recall Procedure (WHO)

Product Recall Procedure Flowchart by World Health Organization (WHO)

Product Recall (HSA)

Health Sciences Authority (HSA): Guidelines On Recall Procedures

Definition:

Product Recall - A permanent removal of the affected products from the market OR a temporary removal for product correction, after which the corrected products may be returned to the market for sale. A specified timeline will be given by HSA to a Company to recall the affected product from the market. The classification and level of recall will depend on the potential hazard of the defective product and the extent of product distribution. These are determined after consultation between the Company and HSA.

Assessment of Recall:

(a) Classification of Recall

A recall will be classified as a Class 1 recall or Class 2 recall depending on the potential hazard of the defective product.

Class 1 Recall - Initiated when the product defect poses a life-threatening situation to users. Some examples of defects that will result in Class 1 recall are non-sterile injections, contamination with toxic substances and products with major labelling errors.

Class 2 Recall - Initiated when the problem or defect is unlikely to cause serious harm to users. Some examples of defects that will result in Class 2 recall include products with minor labelling errors or products which fail to meet product specification or pharmacopoeia standards but are likely to cause minimal hazard to users.

(b) Level of Recall

There are 3 levels of recall, namely: Wholesale, Retail and Consumer. Each recall will be assigned the appropriate level of recall depending on the nature of defect, the distribution networks of the product and the extent of distribution.

Recall to Wholesale level includes - All parties involved in wholesale sale and may include wholesalers and retail pharmacies

Recall to Retail level includes - All restructured and private hospital pharmacies; Retail pharmacies; Medical, dental and other healthcare practitioners' establishments; Nursing homes and other related institutions; Clinical trial centres; Other retail outlets eg. health food stores, supermarkets; Wholesale level

Recall to Consumer level includes - Patients; Other consumers; Wholesale and retail levels

Initiation of Recall:

(a) Recall Initiated by Company - Recall may be initiated by the Company as a result of defective reports from various sources such as manufacturers, wholesalers, retailers, medical practitioners, hospital and retail pharmacists, end-users and members of the public.

(b) Recall Initiated by HSA - Recall may also be initiated by HSA as a result of adverse drug reaction monitoring, product quality surveillance or defective reports from reputable sources.

Definition:

Product Recall - A permanent removal of the affected products from the market OR a temporary removal for product correction, after which the corrected products may be returned to the market for sale. A specified timeline will be given by HSA to a Company to recall the affected product from the market. The classification and level of recall will depend on the potential hazard of the defective product and the extent of product distribution. These are determined after consultation between the Company and HSA.

Assessment of Recall:

(a) Classification of Recall

A recall will be classified as a Class 1 recall or Class 2 recall depending on the potential hazard of the defective product.

Class 1 Recall - Initiated when the product defect poses a life-threatening situation to users. Some examples of defects that will result in Class 1 recall are non-sterile injections, contamination with toxic substances and products with major labelling errors.

Class 2 Recall - Initiated when the problem or defect is unlikely to cause serious harm to users. Some examples of defects that will result in Class 2 recall include products with minor labelling errors or products which fail to meet product specification or pharmacopoeia standards but are likely to cause minimal hazard to users.

(b) Level of Recall

There are 3 levels of recall, namely: Wholesale, Retail and Consumer. Each recall will be assigned the appropriate level of recall depending on the nature of defect, the distribution networks of the product and the extent of distribution.

Recall to Wholesale level includes - All parties involved in wholesale sale and may include wholesalers and retail pharmacies

Recall to Retail level includes - All restructured and private hospital pharmacies; Retail pharmacies; Medical, dental and other healthcare practitioners' establishments; Nursing homes and other related institutions; Clinical trial centres; Other retail outlets eg. health food stores, supermarkets; Wholesale level

Recall to Consumer level includes - Patients; Other consumers; Wholesale and retail levels

Initiation of Recall:

(a) Recall Initiated by Company - Recall may be initiated by the Company as a result of defective reports from various sources such as manufacturers, wholesalers, retailers, medical practitioners, hospital and retail pharmacists, end-users and members of the public.

(b) Recall Initiated by HSA - Recall may also be initiated by HSA as a result of adverse drug reaction monitoring, product quality surveillance or defective reports from reputable sources.

- Health Sciences Authority. (2007). Guidelines on Product Defect Reporting and Recall Procedures. Retrieved on 27th April 2010, from HSA. Website: http://www.hsa.gov.sg/publish/hsaportal/en/health_products_regulation/safety_information/report_product_defects.html

Bread Staling

Monday, May 3, 2010

Bread staling is increased by transglutaminase(TG) addition. Martin, Zeleznak,

and Hoseney (1991) suggested that interactions between the swollen starch granules and the protein network actively contribute to crumb firming. Upon analysis of bread crumb, significant differences in starch–protein matrix have been detected in the course of storage (Blaszczak et al., 2004). TG-induced strengthening effect could increase such interactions and favour bread staling and simultaneous crumb elasticity preservation during storage. The affinity to water promoted by TG in gluten (Gerrard et al., 1998) could also limit the water availability for starch and accelerate its retrogradation. On the contrary, alpha-amylase (AMYL), xylanase (XYL) and protease (PROT) exhibited a significant antistaling effect. PROT showed the most marked effect on reducing hardness, which came accompanied by a significant slowing down in gumminess and chewiness evolution in the time. According with the conclusions of Armero and Collar (1998), crumb firming during storage mainly depends on initial crumb firmness. Through studies carried out on model systems, Rojas, Rosell, and Benedito de Barber (2001) concluded that maltodextrins were responsible for the antistaling effect promoted by addition of a-amylase to bread formulation. They proposed the existence of a mechanism of partial obstruction of starch retrogradation. Jimenez and Martınez-Anaya (2001) proved that water-insoluble pentosans (WIP) were positively correlated with crumb elasticity and hardness during storage. Similarly, the improvement of bread shelf-life through PROT addition possibly would be tied with the increase of the water available for starch, in conjunction with a simultaneous diminution of starch–protein interactions as consequence of the hydrolysis of peptide bonds in the protein molecules. Babiker, Fujisawa, Matsudomi, and Kato (1996) previously reported an increase in the hydrophobicity of protease-treated gluten. Statistical analysis of the textural data during storage proved significant.

and Hoseney (1991) suggested that interactions between the swollen starch granules and the protein network actively contribute to crumb firming. Upon analysis of bread crumb, significant differences in starch–protein matrix have been detected in the course of storage (Blaszczak et al., 2004). TG-induced strengthening effect could increase such interactions and favour bread staling and simultaneous crumb elasticity preservation during storage. The affinity to water promoted by TG in gluten (Gerrard et al., 1998) could also limit the water availability for starch and accelerate its retrogradation. On the contrary, alpha-amylase (AMYL), xylanase (XYL) and protease (PROT) exhibited a significant antistaling effect. PROT showed the most marked effect on reducing hardness, which came accompanied by a significant slowing down in gumminess and chewiness evolution in the time. According with the conclusions of Armero and Collar (1998), crumb firming during storage mainly depends on initial crumb firmness. Through studies carried out on model systems, Rojas, Rosell, and Benedito de Barber (2001) concluded that maltodextrins were responsible for the antistaling effect promoted by addition of a-amylase to bread formulation. They proposed the existence of a mechanism of partial obstruction of starch retrogradation. Jimenez and Martınez-Anaya (2001) proved that water-insoluble pentosans (WIP) were positively correlated with crumb elasticity and hardness during storage. Similarly, the improvement of bread shelf-life through PROT addition possibly would be tied with the increase of the water available for starch, in conjunction with a simultaneous diminution of starch–protein interactions as consequence of the hydrolysis of peptide bonds in the protein molecules. Babiker, Fujisawa, Matsudomi, and Kato (1996) previously reported an increase in the hydrophobicity of protease-treated gluten. Statistical analysis of the textural data during storage proved significant.

- P.A. Caballero, M.Gomez,C.M. Rosell (n.d) website: http://www.aseanfood.info/Articles/11019317.pdf retrieved on 26th april 2010